The entire roof area is then wetted with water which creates an electrical plate at the entire top side of the membrane when charged by the test unit.

Roof negative pressure tester.

Typically a setpoint closer to minus 0 03 inch wc is used.

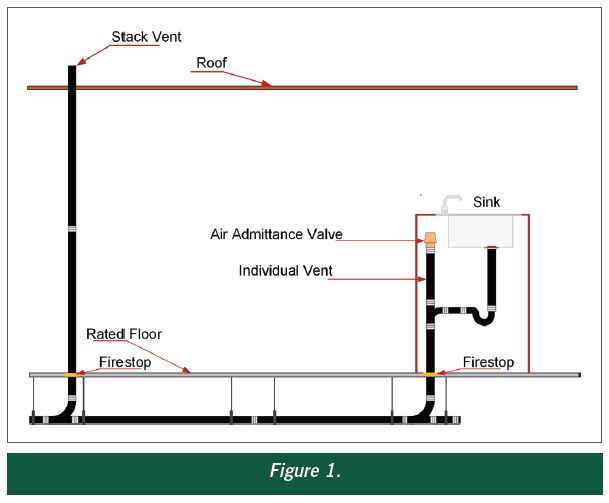

Negative pressure is then applied to the dome starting at an initial pressure of 15 pounds per square foot psf.

28 pcs radiator pressure tester vacuum type cooling system refill kit w case new.

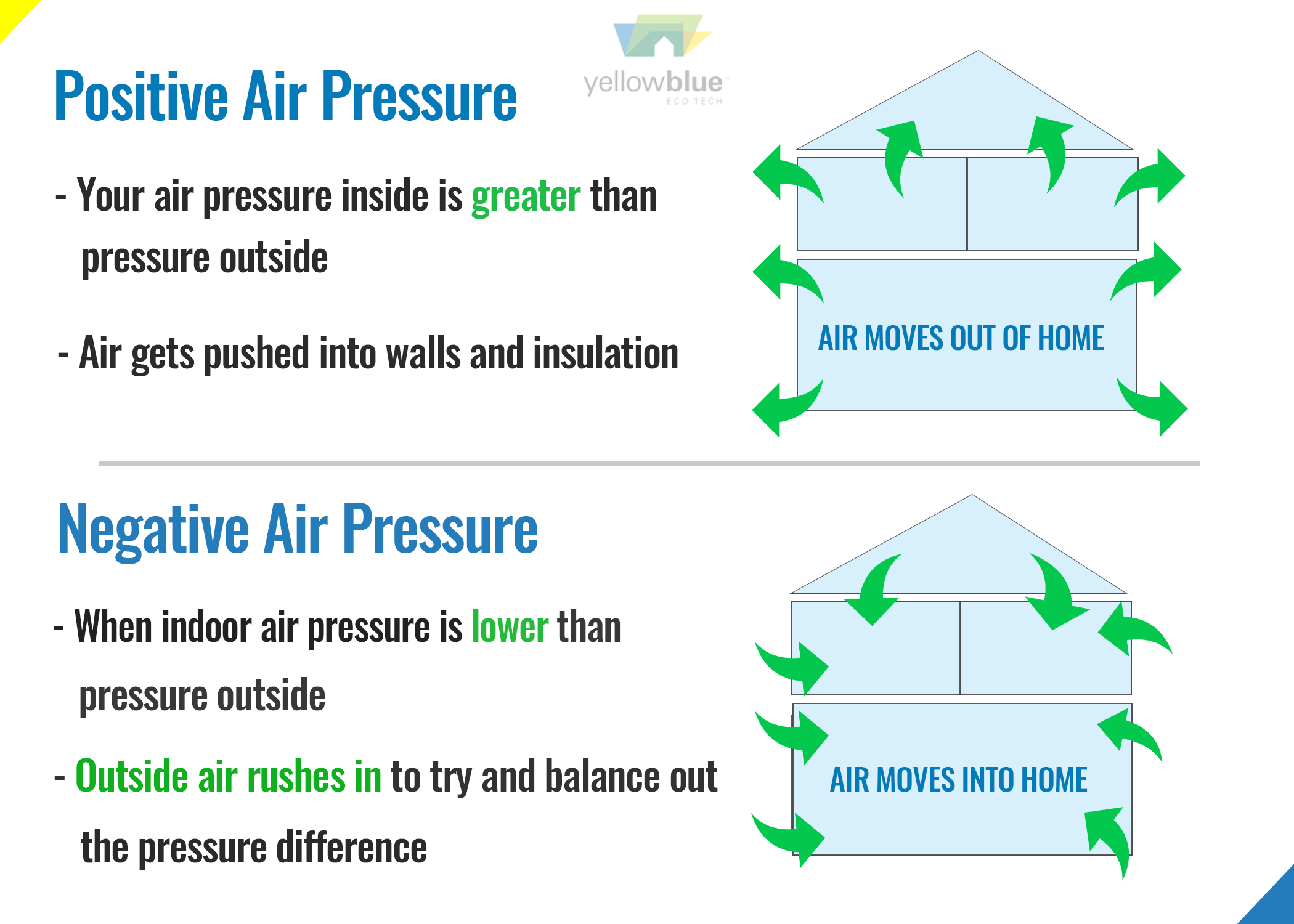

Astm e1680 standard test method for rate of air leakage through exterior metal roof panel systems is used to determine the resistance of exterior metal roof panel systems to air infiltration resulting from either positive or negative air pressure differences.

Negative pressure isolation rooms require a minimum of 12 air changes of exhaust per hour and must maintain a minimum 0 01 inch wc negative pressure differential to the adjacent corridor whether or not an anteroom is utilized.

If air pressure is appropriately negative the tissue will be sucked toward the room.

According to astm test method e1680 covers the determination of the resistance of exterior metal roof panel systems to air infiltration resulting from either positive or negative air pressure differences.

This is the same system being tested throughout all sequences so new specimens are not used as the test progresses.

Plan view of roof with negative pressure distribution shown by contour lines after leutheusser.

The pressure difference results in air being drawn into the room.

Please test the negative pressure air exchange in all airborne isolation rooms daily by following the procedure below.

A deflection bar positioned in the center of the chamber measures upward deflection of the roof membrane.

For heating and cooling solutions negative pressure results in less air being expelled from the air conditioning registers.

It is a standard procedure for determining air leakage characteristics under specified air pressure differences.

When the roof is long the flow can be sucked back down to re attach itself to the roof surface so that the vortex region is effectively sealed off on all sides preventing any reverse flow along the roof to relieve the high suction.

Make offer 28 pcs radiator pressure tester vacuum type cooling system refill kit w case new.

The negative pressure test utilizes a five foot by five foot dome that is placed over the roofing membrane surface.

The test method described is for tests with constant temperature and humidity across the specimen.

Ul 1897 test maintains a positive pressure and increases in negative pressure usually in increments of 15 psf until the system fails keep in mind.

This is an acceptable airflow.

The pressure is increased in increments of 7 5 psf with each increment held for one minute until 1 5 times the design test pressure is reached or failure occurs.

Hold a piece of tissue at the bottom of the closed door.

Cornwell msm 100k cooling system pressure tester kit usa.